When it comes to printing materials, it’s common to see things measured in units like GSM or PT.

But what do these unit systems actually mean? And what are their implications for your packaging and printing?

Understanding the difference between the PT and GSM unit systems will help you better evaluate the weight and thickness of the paper or material you choose to print on.

Knowing this will impact the printing options you choose and will help you determine how to find the right balance between durability and “printability” when it comes to your custom packaging.

The Meaning of PT and GSM in Packaging and Printing

PT stands for The Point System while GSM stands for Grams per Square Meter.

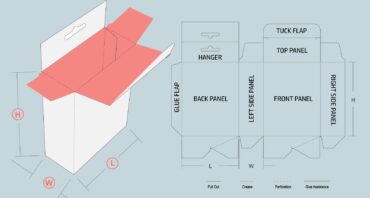

Both of these units of measurement are used to measure how thick stock is. Stock can be paperboard, cardboard or other packaging material. It’s used in folding cartons as well. The weight of the paper also plays a role and is measured in reams. One ream equals 500 sheets of uncut paper (where the paper is at its original, uncut size). You’ll often see paper noted as 80 lb or 80#, which means that one ream of that paper weighs 80 pounds.

In order to understand the point (PT) system, it’s important to know that a point equals .001 inches, so 10 points would mean that there is a stock thickness of 0.01 inches.

GSM is the metric equivalent of points, but is based on the metric system rather than on inches. As you consider different paper levels, it’s important to understand that the thicker a packaging material is, doesn’t necessarily mean that it will be heavier. With that being said, the higher the GSM, the thicker the paper will be.

So, how do you determine the weight of a particular printing material?

By looking at the material itself. It helps to know what different GSM weights of common materials are so that you can have an idea of the thickness of the packaging you need.

Common GSM Paper Measurements

- 35-55 GSM: Newspaper, very thin and delicate.

- 90-100 GSM: Printer paper, more durable than newspaper but definitely not impervious to being handled.

- 120-140 GSM: Posters and bulletins, can withstand the elements more but can still deteriorate if exposed to them constantly over time.

- 210-300 GSM: Magazine covers, better suited to maintaining their form even if they are bent.

- 350-400 GSM: Most popularly referred to as card stock, this thick material is often used to print invitations and business cards and is commonly used for retail packaging as well.

Converting Between the GSM and PT Unit System

GSM is, at its core, the metric version of the PT system and both are used to calculate thickness between each other.

However, the GSM system takes the stock weight into account, but the PT system does not. There are, however, conversion charts that simplify this process and we can convert to and from GSM to PT and vice versa if need be.

Below is a rough GSM to PT conversion chart to help you understand how the conversion process might look in your unique scenario.

| Thickness of Packaging Material | GSM Weight |

| 13 point Pulp | 200 gsm |

| 14 point Uncoated | 270 gsm |

| 16 point C2S / Solid Bleached Sulfate (SBS)* | 350 gsm |

| 18 point C2S | 400 gsm |

| 24 point Uncoated | 405 gsm |

| 24 point C2S / Solid Bleached Sulfate (SBS)* | 460 gsm |

| 40 point Cotton | 600 gsm |

It’s worth noting that since most of the world uses the metric system, GSM is more common overall, however we’re able to work with both systems interchangeably.

How to Compare Paper Weights and Thicknesses

The US-based system can be more confusing than the metric system, but to help make packaging uniform between the different systems, the U.S. version takes into account the weight of the uncut paper (the “basis weight” of the ream). So if you see paper marked with 92#, you’ll know it’s rather thin compared to paper with a weight of 230#.

Why does knowing the weight of paper (or other material) matter, anyway?

You probably don’t think much about the mailers that come into your home every day – until you’re suddenly faced with paper terms like bond, text, book, cover, tag, index and more. But the differences between different sizes and styles of paper are actually a good thing.

Paper has been around for so many centuries that mankind has experimented with all kinds of creative ideas to make it durable and longer lasting. It also means that tried and true methods can be put to work right away to make your packaging stand out from the competition.

What Do These Different Unit Systems Mean for My Product Packaging?

Deciding between points and grams per square meter is just one of the decisions you’ll need to make when you weigh the pros and cons and differences of different types of packaging materials.

Understanding how thick and how heavy you want your packaging to be will not only affect its durability but also the way it’s printed and the features you can use. Some packaging materials will have a smoother surface, which makes printing on them easy. Others are rougher and more coarse which improves their durability, but also affects how easily different printing processes can be achieved.

At the same time, the packaging has to be durable since it needs to protect its contents while showcasing them accurately and in a way that makes the package stand out.

Is it possible to have a package that’s truly the “best of both worlds” – something that evokes quality while maintaining durability as it goes through the printing, labeling and shipping process? The answer is yes!

Speak with a Packaging Expert To Help You Decide on GSM vs PT Unit System

Considering different types of paper weight, thickness, GSM and PT systems and how to choose the right balance between durability, thickness, “printability” and other options can be overwhelming – but that doesn’t mean you have to make that decision alone.

At Refine Packaging, we know that the design, printing and packaging world can be a confusing place to navigate, which is why we’re here to walk you through the process from start to finish and help you enjoy an incredible end result that perfectly positions your product.

We take great pride in taking the time to understand your vision and your goals for your product. Whether it’s standing out with a unique design to separate your product from the crowd, or giving your product a sophisticated and elegant look that was born for unboxing, we have the know-how, expertise and experience to make the end result truly surpass your expectations.

We welcome the opportunity to help you across all aspects of your product’s packaging design. Even if you’re not exactly sure what you want, we have graphic artists on staff who can help bring your vision to life. Once you’ve decided on the design, we can help you choose the right packaging material that helps to protect your product while showcasing it perfectly from every angle.

Plus, we can also help your product stand out in more than just the visual sense. Using the very latest in printing technology, we provide options that are both eye-catching and sensational to behold. From spot UV printing and foil stamping to soft touch coating and lamination that protects and enhances the value of your product, everything we do is done with satisfaction in mind: both yours and your customers.

Interested in learning more about our comprehensive packaging design and printing services? Contact us today for a free, no obligation quote. We’ll take the time to answer any questions you may have about GSM versus PT in print or any other questions you may have about the packaging process.

We know you’ve worked hard to create a product that’s truly extraordinary – now it’s time to choose custom packaging that’s equally as incredible!

Ready to think outside the box? Let's get started!

Get in touch with a custom packaging specialist now for a free consultation and instant price quote.

.svg)

Share