Are you designing a product or packaging label?

If so, it’s critical to understand the basic types of labels, materials, and finishes before working with a professional printer.

Without further ado, let’s dig into the nitty gritty details of product labels, customization options, types of finishes, and so much more!

What is a Product Label?

Labels for products contain graphics and written information that identify a product’s name, its content, its producer, key features, and the directions on how to use, store, and dispose of it.

They can be made of paper, plastic film, cloth, white vinyl, or other material that’s attached to the product, its container, or its packaging. Labeling helps distinguish a product from the others in the same segment.

How Labeling Supports Custom Packaging

Labeling is a component of custom packaging that focuses on promoting and describing your product so buyers know what’s in store for them if they decide to purchase it. This table summarizes the significant role of printed labels in relation to your product’s packaging.

When to Use Printed Packaging vs Custom Labeling

| Packaging | Labeling | |

| Branding | Promotes brand image | Strengthens product identity |

| Safety | Designed for product’s physical protection | Fulfills legal requirements, including ensuring consumer’s welfare |

| Design | Innovative and functional | Creative and informative |

| Structure | Doesn’t need labeling if the product name, brand name, and all necessary information are printed on the packaging material | Needs packaging, although not necessary for some products put on display in-store such as garments |

| Placement | Can serve as the product’s container as in the case of cosmetics, body care products, or shirt boxes | Usually applied on primary packaging such as boxes, bottles, canned containers, and flexible packaging but can also be affixed directly on the product as in the case of clothing labels or electronics |

Importance of Custom Label Printing

Product label printing supports your branding efforts in the following ways:

1. Customization

Your custom labels can feature all the content your buyer needs to know about your product. Once you’ve decided on what information and images to include in your label, you can work with a designer or your printer for its layout, shape, and sizing. You can also do it yourself, using an online design tool such as Adobe or Canva.

2. Product and Brand Recognition

A designer can help you come up with ideas that will pique your target market’s interest and make your product easy to distinguish from your competition. Meanwhile, professional printers ensure quality and consistency in the overall look of your custom labels.

When your product has several variants (i.e., flavors or scents), you can design labels that can make sorting easier for wholesalers, retailers, and buyers.

3. Trust Building

Brands can better convince consumers to pick their products if their labels honestly state their contents and benefits. According to research, 97% of beauty product shoppers seek this kind of transparency.

4. Legal Compliance

To comply with industry and government standards on health and safety, include warnings, health hazards, emergency solutions, and other lawfully required information on your personalized labels.

5. Tracking

You can design custom quality labels to help you track products from production to delivery to your distribution points. Bar codes and other stockkeeping unit identification are necessary aids in current warehousing and shipping systems. They’re also useful in the case of product recalls.

6. Marketing Promotions

Labels for products can also feature information such as discounts, coupons, or other special offers to increase your product’s appeal.

General Types of Custom Packaging Labels

Labels are made to adhere well to their product’s packaging. Here are the most popular types of printed labels today:

1. Pressure-Sensitive Labels

The most common of all custom labels, pressure-sensitive labels are applied on packaging by hand or machine. They’re made up of a facestock (more info on this later) with or without a top coat and an adhesive with a liner. The details of a label’s anatomy are found in the next section. For optimum adherence, brands and manufacturers consider the surface or material that the label will be attached to.

- Dry peel: Dry peel labels have semi-permanent adhesives. They’re often designed to serve as coupons that buyers can peel off and present to get discounts or to join a contest.

- Reseal: Resealable labels allow customers to seal them back into the product packaging to keep its remaining contents fresh before use or consumption.

2. Shrink Sleeves

Also referred to as a shrink wrap, these polymer plastic films cover entire containers. The film is exposed to heat from a handheld gun or passes through the heat tunnel of industrial label printers to make it fit tightly around the product. Many bottled beverages that need refrigeration have heat-shrink labels.

3. In-Mold Labels

These preprinted polypropylene (PP) labels are injected into a mold where the plastic packaging container is formed. Once the packaging takes shape, the label is already fused into the container. This makes these labels look like they’re part of the container instead of a separate stock placed on its surface. Some laundry detergent bottles and food tubs (yogurt and butter) use this type of labeling.

4. Die-Cut Labels

These labels are made for uniquely shaped containers. They use a die and a press to cut the custom shapes.

5. Thermal and Thermal Transfer Labels

A warm printhead (direct thermal) or heated ribbons (thermal transfer) print words or graphics on the label material instead of ink. These individually cut custom labels are usually used for price tags, shipping, and bar coding. They have a short life span and are prone to change color when exposed to another heat source.

The Anatomy of Personalized Labels

Pressure-sensitive labels for products mainly consist of these five parts:

1. Facestock

The facestock is the specialty paper, film, or fabric that contains the graphics and text. Being the main part of the label, it’s the layer where the ink is applied and onto which the top coat and adhesive are anchored. It gives your custom labels structure, shape, and size.

2. Ink

Various types of inks are used to print text, graphics, and photos on the facestock: fade-free UV inks, nearly odorless and affordable water-based inks, and durable solvents that don’t require a top coat. Meanwhile, you can use specialty inks for unique metallic and fluorescent effects.

3. Top Coat

Not all labels need top coats (uncoated), but they’re necessary for facestocks made of plastic film. Top coating helps the ink spread out and cling to these types of surfaces. Meanwhile, varnishes and laminates are examples of top coats for paper labels. Besides providing an aesthetic finishing touch to their surface, this layer protects the print on labels from fading due to moisture, sunlight, or rough handling.

4. Adhesive

The adhesive layer is what sticks to your product’s container or packaging using pressure or heat. Your choice of adhesive material will depend on your packaging material, its shape, the environmental conditions it will be subject to, and your desired level of permanence.

Here are the four basic types of adhesives:

- Peelable: Labels with removable adhesives can be taken off the surface without leaving any residue or destroying the label itself, compared to permanent ones. But removable adhesives can permanently bond to a surface when they’ve stuck to a surface for an extended time or due to environmental exposure.

- Permanent: Permanent adhesives can stick to moist and rough surfaces. Taking them off will usually result in destroying the facestock. They’re recommended for flat surfaces.

- Semi-permanent: Also called repositionable adhesive, this type lets you peel off labels from their surface in the short-term for adjustment. They settle and harden once reapplied to their new position.

- Freezer: Custom labels with freezer adhesives stay put on the products or their packaging without peeling or cracking—even in below zero settings.

5. Liner

The liner protects your adhesive until it’s applied to a surface. It can be made from paper or film.

Facestock Materials

Paper and film are the most common materials used for the facestock of custom labels.

Paper

As ink settles well on paper, text and images look very sharp on this surface. Compared to film stock, they’re available in different colors and textures and are more affordably priced.

Paper-based labels are most appropriate for dry and cool indoor applications as they can only handle limited exposure to moisture (water and oil), extreme temperatures, and abrasion. Paper labels are best used for non-perishable goods like canned food as well as household and beauty products like soap bars.

Some common paper facestock examples for labels include:

- White paper: White paper is made of high-quality paper that’s bright and opaque white. It can have a matte, semi-glossy, or glossy finish.

- Metallic paper: Metallic paper gives products a polished sheen. Some of the available colors include gold, rose gold, silver, bronze, and copper bronze.

- Recycled paper: This brown-colored paper stock can give products a vintage, rustic, or handcrafted look. Facestock of this type includes kraft and the black and velvety vellum labels.

- Estate 4: Estate 4 paper is the most durable of the paper stocks due to its “wet strength” or water resistance. It’s also colored white and has a subtle linear texture.

Film

Facestock made of plastic film are tear-free and can conform to the shape of curved or other oddly shaped containers. They’re long-lasting due to their oil and chemical resistance. Film stocks also hold up to spillage, condensation, sweating, and sun exposure. They often have permanent adhesives and can attach to textured surfaces and painted metals.

- Vinyl: Technically called polyvinyl chloride (PVC), these plastic stocks made of ethylene and chlorine have a slight flex and are dishwasher-safe. They can withstand extremely cold environments and can last for up to five years, based on the vinyl formulation. These labels work best on vehicle windows (static cling vinyl) and bumpers, sports equipment, outdoor marketing devices, and frozen food that has to stay in below-zero temperatures for long periods of time. They come in white and clear varieties.

- Polypropylene: Biaxially oriented polypropylene (BOPP) is slightly thinner than vinyl and works well on contoured containers as they can stretch horizontally or vertically (biaxial). They have a medium lifespan (six months to two years) compared to vinyl and polyester stocks. They’re advisable for labeling smaller refrigerated items, such as meat, sauces, dressings, cheese, jams, and beverages. They’re available in white, silver, and transparent versions.

- Polyester: Also known as polyethylene terephthalate (PET) and mylar, polyester facestock can last over 10 years, making it the most durable of all film stocks. They’re ideal for industrial use due to their chemical and moisture resistance. These materials remain intact in extreme temperatures and under UV exposure. They’re the most expensive of all three plastic stocks. Professional printers can offer to make these labels using white, clear, and metalized polyester.

- Squeezable film: This material is best for squeezable bottles and tubes, including lotion, sunscreen, toothpaste, and other beauty and health products.

Different Types of Finishing for Customized labels

Labels need the right finish or top coat to make them last and look good longer. Here are some of the most popular label finishes:

1. Varnishes

Varnishes coat facestocks in clear liquid, making labels smoother and more resistant to spills and scuffs. They cost less than UV coatings and laminates but have the least staying power. A glossy varnish can make image-heavy labels stand out, while a non-reflective matte varnish can produce a subdued but professional effect. You can use spot varnish to highlight specific elements on your custom labels like your logo, brand name, or graphics.

2. UV-Resistant Coatings

This type of finish involves applying a special liquid on a label’s facestock and then curing it in ultraviolet light. The coating later becomes a permanent sunscreen that prevents your text, design, and colors from fading and other possible damage.

Although this is usually a glossy finish, UV coating is also available in semi-gloss and matte. You have the option to cover the entire surface of your label (overcoat) or just selected sections (spot coat).

3. Laminates

Laminates are a thick film-like coating. They offer the greatest protection against sunlight, moisture, and abrasion. A glossy laminate sharpens the content and color of the label’s facestock while a subtle matte finish can give your custom labels an elegant touch.

4. Foils

A hot foil is composed of metalized PET film with heat and pressure-activated adhesive, which sticks well on glass bottles and cans. Hot foil can give a sophisticated look to custom wine labels. Meanwhile, a cold foil uses UV-curable adhesive, so it’s suited for thinner packaging material like plastic that can’t withstand high temperature.

Finishing Formats: Roll, Sheet, and Fan-Folded

You can order custom-made product labels by sheets or rolls. Let’s see when to best use each of them.

1. Sheet Labels

When it comes to label sticker printing, sheet labels come in sheets of different paper sizes, although the most common is the A4 size.

Using sheet labels is the best option for short runs or smaller quantities (below 250 labels), including testing out the packaging of your new product or selling seasonal products. But some professional services can also offer this type of printing for a larger project.

2. Roll Labels

Roll labels are spun on a cardboard spool and get printed on using a roll printer. They’re advisable for bulk orders, including those that need specialty ink printing. They can be die-cut in any shape and size. Custom roll labels also work best for labels containing unique content per piece, such as bar codes or shipping labels.

3. Fan-Folded Labels

These pressure-sensitive custom labels are on a continuous backing sheet that folds along its perforations accordion style. This self-stacking format makes a great alternative to the roll format for shipping, address, and barcode labels.

Designing Your Own Labels

How do you come up with a label that will attract customers to choose your product? Here are some pointers.

1. Know Your Target Market and Existing Buyers

What’s your target demographic? It’s important to establish who your buyers are when designing your custom labels—and even your stickers and decals, for that matter. Determine their ages, gender, location, lifestyle, educational levels, income, values, and pain points or challenges that your product can solve. Listen to relevant feedback so you can personalize their experiences. Personalization is generally the difference between successful and disappointing campaigns.

Some relevant statistics to keep in mind:

- 56% of consumers become followers of a brand that “gets them” or understands their needs, and 89% choose to patronize a brand that shares their values.

- 64% of food shoppers spent more on products whose labels contained popular phrases such as “fresh,” “no sugar added,” “whole grain,” or “organic.”

2. Research the Competition

Examine and compare the attributes of your competitors’ marketing and branding materials, such as labels, flyers, stickers, and packaging. Take a close look at the color, typography, imagery, size, shape, and target demographic. What do consumers like and dislike about your competitors’ labels? What colors or other design elements are they drawn to? What are the major differences between your labels and theirs?

Take note of those elements that work well and brainstorm ways you can customize and improve them. Your custom labels should command attention when displayed side by side with similar products in-store. For e-commerce items, check if your labels will register well on the camera for photography and video shoots. You can also create custom shipping labels to elevate the look of plain cardboard packaging.

3. Determine the Essential Product Information to Include

Decide Your Information Hierarchy

List down all the product details that you want your buyers to read on your label. Afterward, arrange them according to importance with the product name and brand name on top. For instance, in a food product, your brand’s logo, product’s weight, and other graphics should go in front. Meanwhile, instructions, expiry date, company’s contact information, and others can appear at the back.

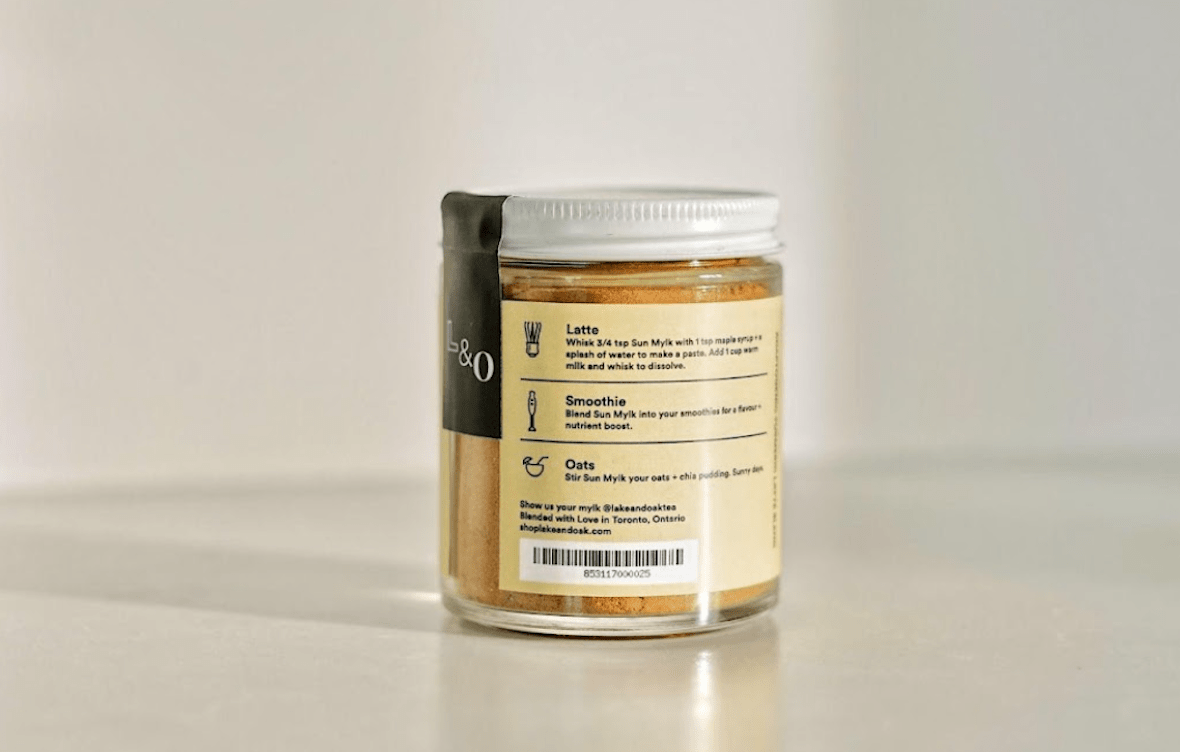

In the image below, the brand’s logo, which includes its brand name and tagline, is on top of the label. The product’s name appears just below the brand’s logo. Its ingredients are listed in a smaller font and occupy the lower half of the label. The product’s net weight and storage instructions are printed at the bottom of the label, in a much smaller-sized font.

Meanwhile, this product’s back-of-pack label includes directions on how to prepare its contents. The company’s contact information, its country of origin, and bar code also appear there.

Highlight Your Unique Selling Point

Why would a customer want to buy your product instead of another brand? Research and create a profile of your leading competitors. See what your competitive advantage is over them so you can incorporate it in your selling point.

You also need to know what your target market needs and wants. Run a survey using your social channels or email questionnaires. Find out what your consumers’ pain points are and how your brand can help overcome them. After analyzing their feedback, you’ll be able to go beyond enumerating your product’s features or what it can offer. You can tell your buyers how your product can meet their needs and wants.

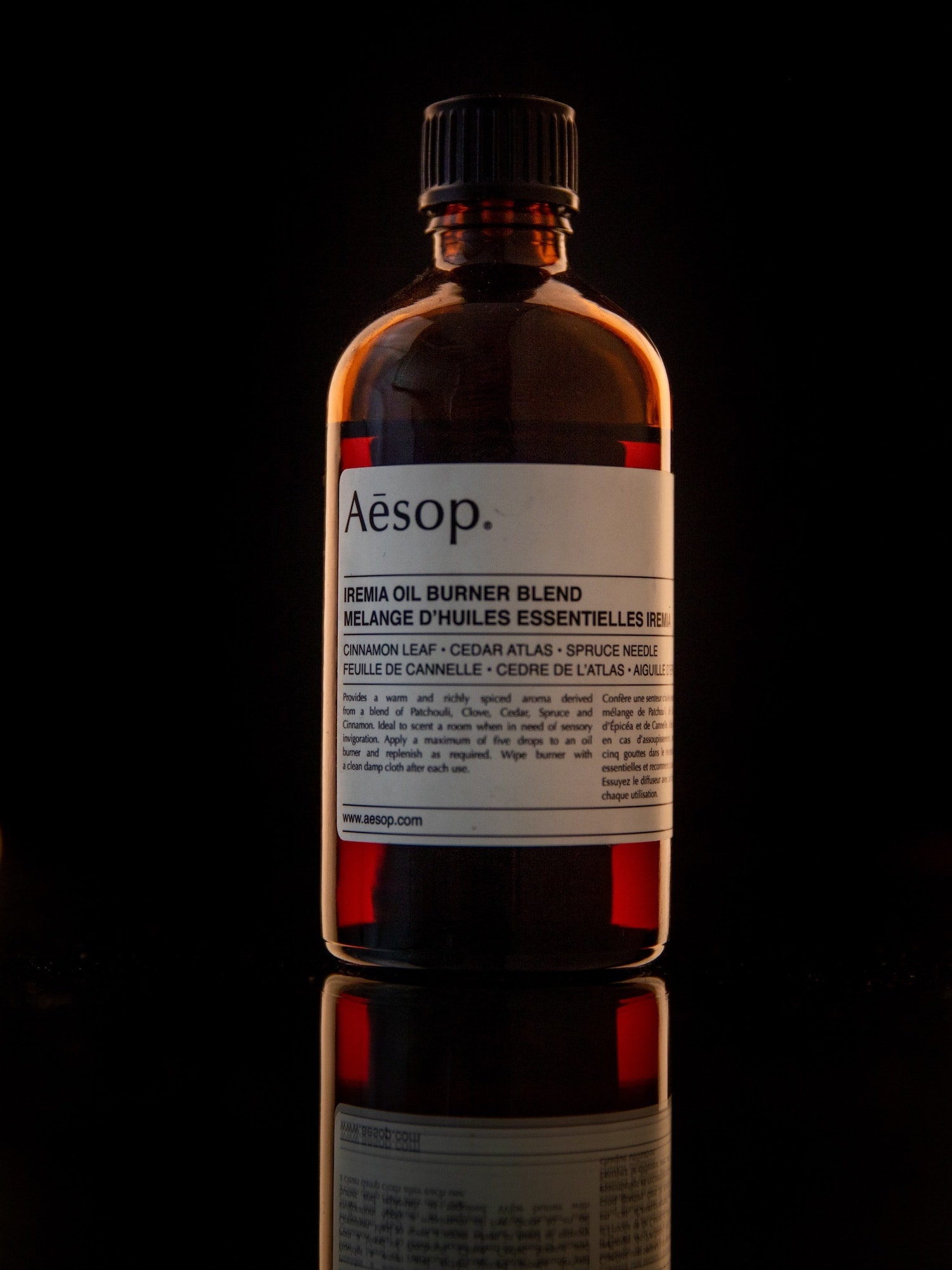

Below, the brand cited the benefits of its iremia oil burner blend on its rear label.

Include Legally Required Content

Check what your national, local, and industry laws state about the mandatory information that a custom label should carry.

In the United States, the Federal Hazardous Substances Act requires household items like cosmetics, cleaning products, and art materials to have storage and safe handling instructions. Thus, custom labels should carry signal words such as “poison”, “caution”, or “danger” and steps for first-aid treatment.

Food and beverage manufacturers are required to disclose the nutritional value and ingredients used in their products on the packaging. According to an American Heart Association survey, a majority of food shoppers (59%) always read packaged food labels before buying the product for the first time. The U.S. Food and Drug Administration also expects manufacturers to list the allergens, additives, and other chemicals used.

Many plastic and latex products, such as children’s toys with toy parts, should carry choking hazard warnings, according to the Consumer Safety Protection Commission.

Use Customer-Friendly Language

Again, knowing your target customers is important here. You can review social media comments and feedback to pick out the phrases they commonly use. Also, use the results of your surveys and questionnaires to know what words resonate with them.

Besides using easy-to-understand language, be honest about what your product contains. In the latest Innova Consumer Survey, transparency emerged as the top need among food shoppers. This means including the ingredients list in plain English, certifications, and in-depth nutritional information.

Provide Space for Your Barcode

Barcodes are now necessary in helping you keep track of your products, whether inside the warehouse or the store. Aside from shipping and inventory purposes, they also protect your products and brand from counterfeiters. You can also use barcodes for promotions to reward consumers and build loyalty.

4. Consider the Packaging Materials

There are several factors to think about when deciding on the type of material to use for your individually cut labels. The label material refers to the facestock or that which receives the printed text, image, and barcode.

Shipping Container Size and What It’s Made Of

Will you be sticking the label on cardboard boxes or glass, can, or plastic shipping containers? Does it have a solid color or is it transparent? And how large (or small) is it? You need to measure the surface onto which you will apply your label so you can get the right fit and pick the correct adhesive.

Printing and Finish

Pick a material that carries your preferred texture—matte or glossy—and can take the kind of coating or finish that you want it to have such as hot stamping, embossing, debossing, and others.

Environmental Factors

Your chosen material should stay durable throughout your product’s lifespan. What kind of environment will it be exposed to? UV light can fade out inks, while water exposure can cause the ink to smear or get washed off the label.

Products that are subject to extreme cold such as refrigerated food may need freezer-grade adhesives. Meanwhile, others that are exposed to heat, such as products you take with you outdoors, are prone to peel (label lift). Special equipment can remove condensation to prevent this problem or adhesives should be allowed to fully set 24 hours after application.

Some custom labels may need foam or tape to reduce friction, while labels placed on wearables may need skin-friendly applications to endure stretching and sweat.

5. Select Your Colors and Fonts

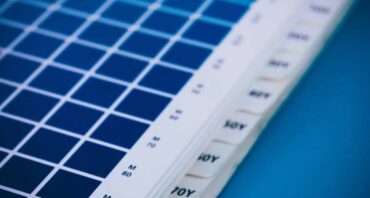

Amid the possibilities, it’s best to stick with your core brand colors to strengthen your brand’s identity and reduce the chance of counterfeiting. Also, it’s best to refer to the Pantone Matching System to determine how your brand colors will register on preferred label materials.

Color

Colors are typically associated with certain emotional or psychological responses:

- Green: Green symbolizes growth, a fresh start, health, nature, peace, and wealth. Its darker shades can imply wisdom and prosperity. It’s used by brands that are into organic food and pro-environment products. Some investment firms also use green as it stands for the color of money. Goes well with: blue, yellow.

- Blue: Like green, blue can evoke a sense of tranquility and openness. Many banks and communications firms use this color as it embodies intelligence, security, and reliability. It’s also found in many home cleaning products as it conveys a sense of tranquility and openness. Goes well with: green, yellow, red, and orange.

- Red: Red exudes excitement, warmth, and strength. Brighter shades can stand for high energy while burgundy, maroon, and darker shades can represent elegance. Many food and beverage brands include this color in their packaging. Goes well with: yellow, black, blue, white, and green.

- Orange: Orange also radiates vitality and a sense of adventure but by a notch or so lower than red. It’s also linked to confidence, creativity, friendliness, and innovation. Innovators, technology, sports, recreation, and home improvement brands carry this color. Goes well with: blue, black, and white.

- Yellow: Yellow stands for joy, clarity, optimism, and youth. It’s recommended for children’s products, bath and body items, candle brands, and honey distributors. But it’s also ideal for warning labels and products containing powerful chemicals. Goes well with: red, blue, and black.

- Purple: Purple suggests nobility, luxury, and ambition. It’s also associated with youth, creativity, and spirituality. Several creative startups have opted to use this color, and so have some beverage companies for their wine bottles. It’s also found on custom labels of some anti-aging and high-end skincare products. Goes well with: yellow, blue (when mixed with deep purple).

- Pink: Pink is the color of romance, softness, serenity, and fantasy. Many skincare and beauty business brands tap this color. Goes well with: blue (when combined with baby pink), black.

- Black: Black evokes power, sophistication, solemnity, or mystery. It’s a popular choice among liquor brands and candlemakers. Goes well with: white, yellow.

- White: White represents simplicity, cleanliness, and innocence. It can also stir up feelings of lightness or reverence for what’s supernatural or sacred. The color is a common preference among medicinal, health and beauty, and household brands. Goes well with nearly any color.

- Gray: Gray indicates neutrality, balance, and professionalism. Information and technology, architecture, and industrial circles favor this color. Goes well with: brown.

- Brown: Brown creates feelings of comfort and dependability. Organic products as well as tea, coffee, and chocolate brands include this in their brand colors. Goes well with: purple, gray.

As a general principle, the darker the hues, the more serious your message is compared to bright and fun shades.

Typography

Just like in color selection, the fonts you choose for your custom labels should resonate with your brand. There are mainly four basic types of fonts:

- Sans serif: These fonts don’t have “feet.” A few examples are Arial, Helvetica, Century Gothic, and Corbel.

- Serif: These traditional fonts have feet. Examples include Times New Roman, Garamond, Georgia, and Baskerville.

- Slab serif: Although not very popular, these fonts have thick and bold serifs like Rockwell, Memphis, and Soho.

- Script: Examples of these cursive or handwriting-like fonts are Freestyle Script, Lavanderia, and Yellowtail. The upper case of “Unreadable” script fonts like Precious and Shathika can be used as the first letters of paragraphs.

- Display: Inspired by handcrafted signs and calligraphy, display or decorative fonts are best used for headings instead of body copy. Algerian, Pinewood, and Monoton are examples of display fonts.

To ensure you pick the appropriate font for your product labels, it should:

- Reflect the qualities of your product and brand voice. You can select chunky and loud fonts for fun and affordable products. Meanwhile, clean, light, and delicate or formal-looking fonts are suitable for high-end products.

- Appeal to your target demographic

- Meet regulatory standards, clearly presenting product benefits and instructions

- Work well with your graphics

While you can choose between classic and more cursive fonts for your product names and front-of-the-package details, it’s best to use simple but legible fonts for the rest of the product information such as ingredients list and directions for use.

When you come across a font that you like while browsing the web, you can discover its name by using online font finder tools.

6. Use High-Resolution Images

When preparing artwork to use or submit to your label printing service provider, choose images with a resolution of at least 300 dots per inch. Avoid pulling images uploaded on a website as they’re usually low-resolution and will look blurred when printed.

7. Conduct a Test Survey

You can work with a market research firm to hold a label test survey so you can tweak or further customize its design or content, depending on the feedback, before launching a full custom label printing run.

Set Your Brand Apart with Stunning Custom Labels

The team of creatives at Refine Packaging can turn your design ideas into reality, creating beautiful customized labels that will delight your customers and build brand affinity, all at a reasonable price for your business.

Contact us today for a free, no-obligation quote on your custom packaging needs. We’ll support you in creating personalized labels that convey your brand’s unique personality, have amazing social appeal, and protect your product no matter where it travels.

Ready to think outside the box? Let's get started!

Get in touch with a custom packaging specialist now for a free consultation and instant price quote.

.svg)

Share