Color can make or break a product’s packaging design.

Think about the red and yellow arches that are printed on every McDonalds happy meal. They’re iconic. And part of what brings those colors to life are the RGB and CMYK color models that are used during the printing process for each and every one of those happy meal custom boxes.

So what is CMYK color in printing? What does CMYK stand for? And what does the RGB color model have to do with it all?

RGB and CMYK are both color modes used in the printing process. But when you’ll use each one depends on a variety of choices that you’ll need to decide before your packaging box design is printed. Let’s jump right in.

What is the CMYK Color Model?

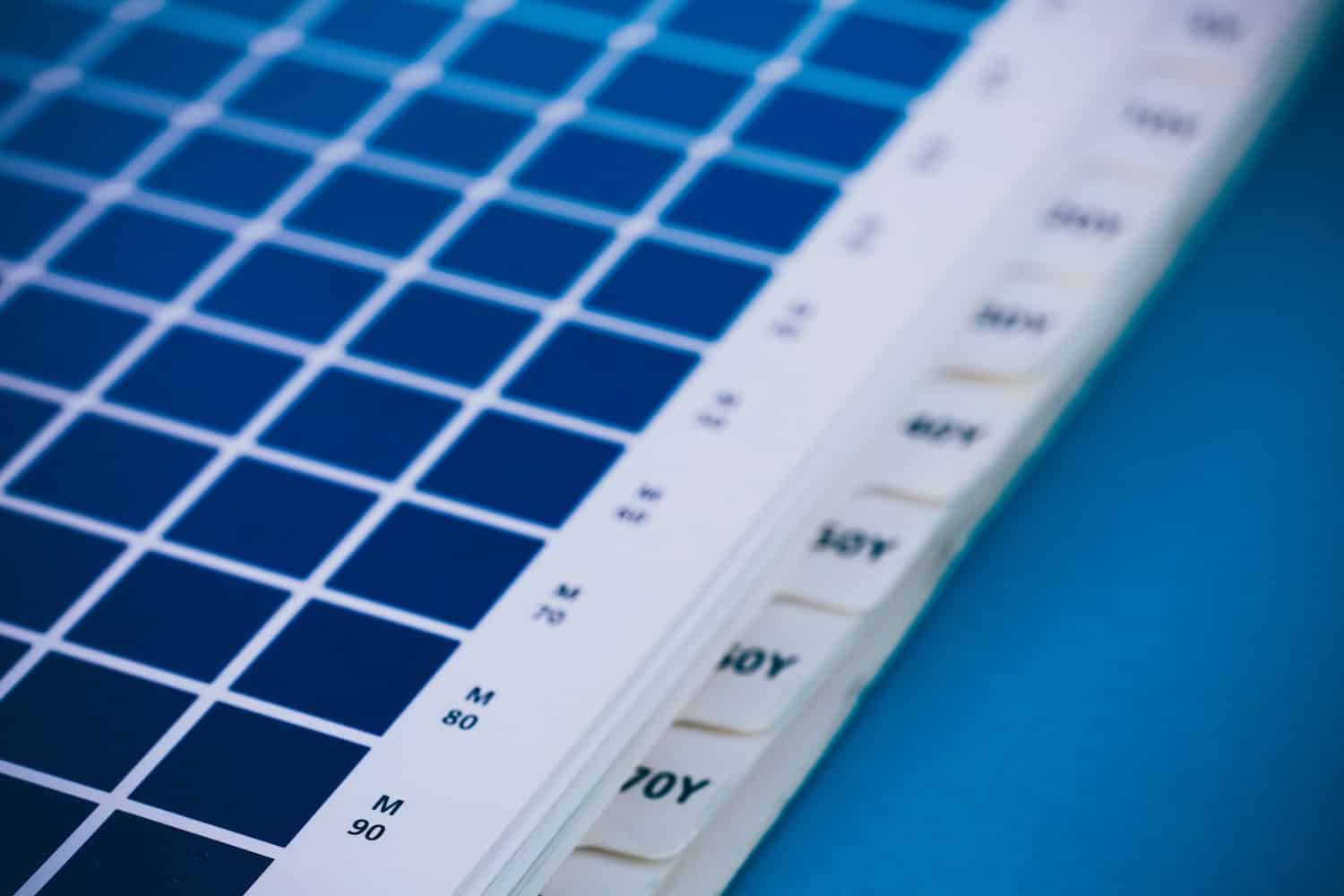

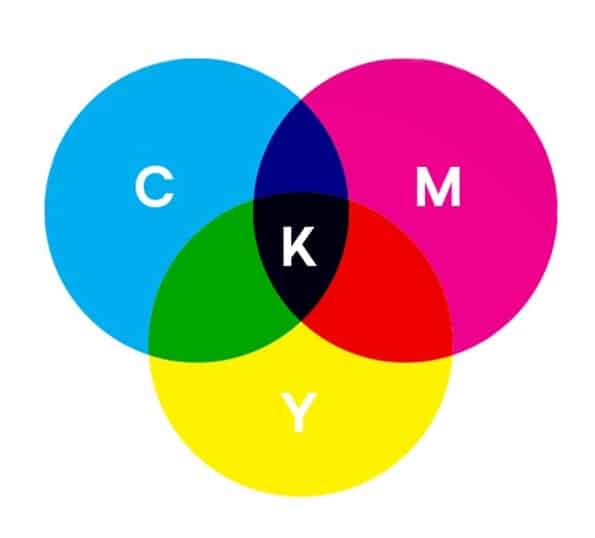

CMYK stands for Cyan, Magenta, Yellow, Key (Black) and is used for printed materials. In the CMYK color model, all colors start out as white, until layers of cyan, magenta, yellow and/or key (black) ink are added to reduce the initial brightness until the desired color is achieved.

Offset printing machines combine varying levels of these 4 colors using physical ink in the CMYK process called “subtractive mixing“. When all of the colors are mixed together, the result is pure black.

When Should You Use the CMYK Color Model in Printing?

CMYK is best used for printed material. It’s more accurate than RGB, which we’ll describe below, and allows for subtle differences in shade and tone (subtleties that digital devices cannot “see” but our eyes can still perceive).

If you use CMYK printing, you’ll have more accurate results compared to the RGB color model. Learn about the Pantone Color Matching System (PMS) which was created to help standardize color variations when using CMYK.

What File Formats are Best for CMYK?

PDF is the best file format for CMYK printing because of its wide compatibility. For logotypes and other product design elements, Adobe Illustrator’s AI format is often used, as is a similar standard from other vector software of EPS. We work with all of these types of formats, so feel free to use whichever one you prefer and you can be confident that we’ll be able to work with it.

What is the RGB Color Model?

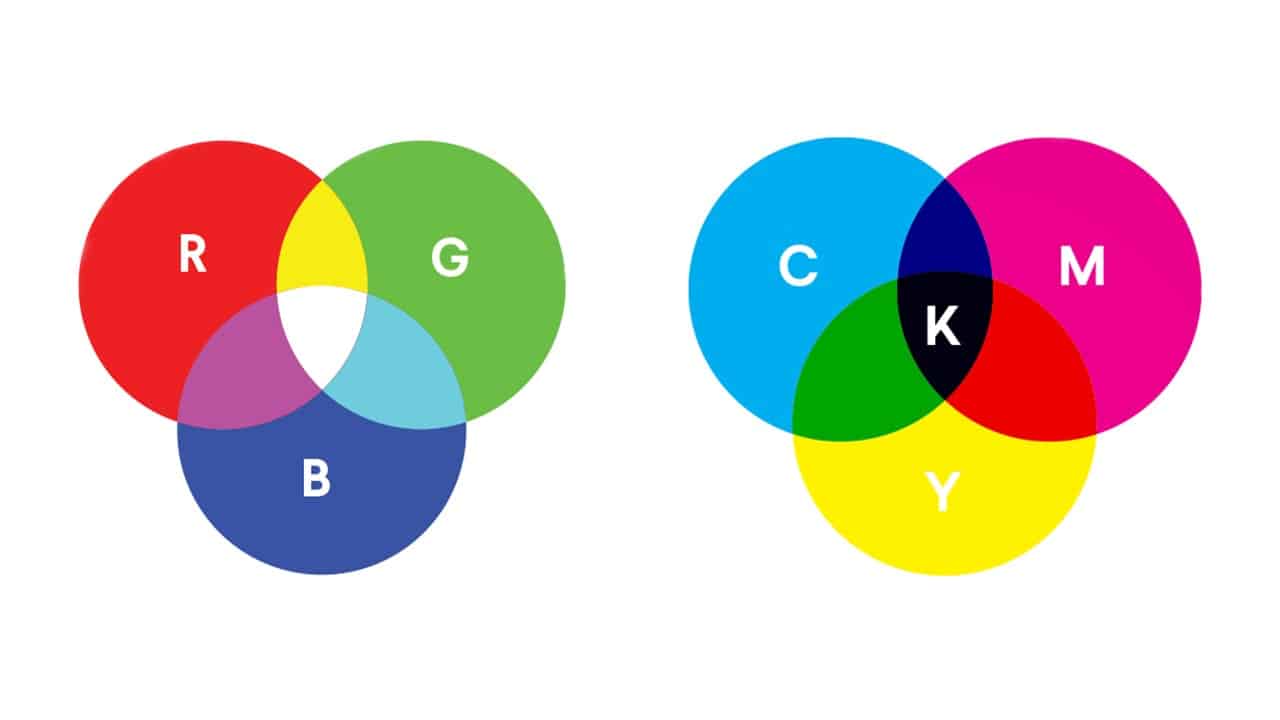

The RGB color model is an additive color model where the primary colors or light units – red, green and blue – are combined in multiple ways at different levels of intensity to produce a vivid and wide range of unique colors (known as “additive mixing”). RGB is typically used for digital graphics, where the images will only be seen on screen.

In the RGB color model, all colors start out as black. As more red, green or blue are added and at different intensity levels, the colors change accordingly. At their highest levels of intensity, the light from the device is mixed completely at the same level for each color, creating pure white.

From here, the designers can vary the saturation of color, the shade of the color and its vibrance level in order to get the exact color they want, based on how the light and darkness are shown on the screen of the device they’re designing for.

When Should You Use The RGB Model in Printing?

The RGB color model is typically only used for designs that will be viewed solely on screen. If you’ll be using your design both on screen and in print (such as on your website and your product packaging), it’s normal to have a version as RGB and one as CMYK, which we’ll outline in more detail below.

The most common uses for RGB are things like graphics, buttons, icons and web-based logos.

What File Formats are Best for RGB?

JPG is normally the standard for RGB files, normally because it strikes a good balance between quality and file size. If everyone will be working with Adobe Photoshop, PSD is a commonly used format. Use PNG as the format if you want parts of the image to be transparent, or if the image is made up of a few colors. Icons, buttons and other graphics are often saved as PNG files.

If you’re going to be using animation, GIF is the ideal format to use. You’ll want to avoid BMP, TIFF, EPS and PDF as there are often compatibility issues with these older formats, and the file sizes are unnecessarily large and cumbersome to work with.

What’s the Difference Between RGB and CMYK Printing?

The difference between these formats is that the colors will render differently depending on whether they’re viewed on a screen (RGB) or on a print device (CMYK). The rendering of the different modes depends on how the colors “mix”.

RGB printing has a larger range of possible colors, while CMYK has the ability to make the colors more vivid. That’s why, if you transfer a CMYK image, it will show less of a range of colors and may look slightly different on screen than in print.

Conversely if you tried to print an RGB image, it would look muted and dull in terms of its coloration. It is possible, however, to convert RGB to CMYK using software, so if you have an RGB or CMYK image and you need it changed to the different mode, it’s no problem to do this in Adobe Photoshop or Adobe Illustrator.

We can convert your logo or other file formats before printing if you need this done, to ensure excellent results with your printed design. Keep in mind that there is no 1:1 correlation between the colors, but they can come very close to matching each other.

Keep reading: Learn about embossing vs debossing, spot uv for printing, aqueous coating, soft touch coating and lamination as you explore your packaging and printing needs.

Still Have Questions About Working with CMYK or RGB Color Modes?

At Refine Packaging, we understand that you may still have questions about the different color modes than what’s answered here. We’re happy to convert your files so that the end result will look flawless in print.

We can also advise you on the best type of retail packaging to fulfill your product development vision and ensure that your product is treated with the best possible care and precision in printing to have a package that equally matches your brand’s personality and style.

And even if you’re not sure exactly what sort of design you want, we have a team of artists from a variety of backgrounds who are ready to step in and help. We’ll take the time to get to know your unique vision for your product, as well as who your target audience is, so that we can create a congruent match between product and customer.

We then work to better understand your budget so that we can make cost-effective suggestions that maximize your product’s packaging design without breaking the bank.

Finally, when all is said and done with the design, we can suggest packaging options that fit the theme, box size or style of the look you want to convey. Whether it’s classy and sophisticated, or you want to draw attention to your logo or lettering, there are numerous print styles and processes that can help you achieve all of this and more.

Contact us today for a free quote on your product packaging design and printing needs and let’s work together to create a professional look that perfectly matches your brand and vision!

Ready to think outside the box? Let's get started!

Get in touch with a custom packaging specialist now for a free consultation and instant price quote.

.svg)

Share