Understanding color systems is vital when you want your packaging design to look good in real life as it does on a computer screen.

Although you can give this task to your graphic designer and print manufacturer, knowing the industry’s standards for color can aid your selection process and level expectations about the printing outcome.

This article is primarily about CMYK, but we’ll also touch on the other two most prominently used color modes in the design world—RGB and Pantone. Color models are the building blocks that represent an image and have their own gamut or color ranges. They achieve unique levels of color detail according to their number of channels or colors. Their comparison can deepen your appreciation of CMYK as the most effective color model for printing.

Defining CMYK

What is the CMYK Color Model?

CMYK stands for Cyan, Magenta, Yellow, Key (Black) and is used for printed materials. In the CMYK color model, all colors start out as white, until layers of cyan, magenta, yellow and/or key (black) ink are added to reduce the initial brightness until the desired color is achieved.

CMYK stands for the four ink colors used in printing—cyan, magenta, yellow, and black. The CMYK system blends these colors to create about 16,000 variations. In the color wheel:

- Cyan falls between blue and green, but most people see it more as the former color. It’s similar to sky blue or the aqua blue color seen in tropical ocean waters.

- Magenta falls between red and blue, but most consider the color closer to red instead of blue. It’s comparable to fuchsia and hot or deep pink. People associate this color with bougainvillea flowers and orchids.

- Yellow is the lemon yellow, canary yellow, and gold hues we see in nature, such as sunflowers, daffodils, and sunshine.

- Black is the color of coal, volcanic rock, and some gemstones like obsidian and onyx. The other meaning of “K” is “key” because the black ink plate provides fine details, depth, and contrast in the resulting image. Thus, “key plate” is the other term referring to the black plate.

In theory, mixing cyan, magenta, and yellow results in black. In reality, however, their combination results in a muddy dark gray. Moreover, a 100% three-color blend soaks the paper in ink, slowing down the drying process.

How Does CMYK Work?

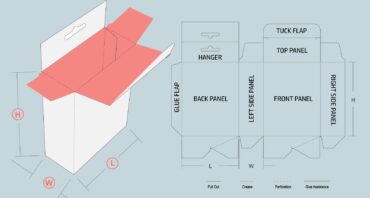

When you bring your packaging design to a commercial offset printer such as Refine Packaging, the company separates your file into component colors using what’s known as the color separation process.

Each CMYK ink color has a separate printing plate, and the ink transfers or offsets from this plate onto a rubber blanket and then on paper as tiny dots. The colors become solid and continuous as the dots overlap until the four-color process or process printing is complete.

Meanwhile, digital printing doesn’t require color separation. The ink goes directly onto paper instead of plates, making them a cost-effective option if you have a lower quantity printing order.

The printer copies the image from your file. From there, individual CMYK color droplets produce the illusion of a colored image. Inkjet printers use ink while laser printers—used in commercial applications—use toner.

RGB and Pantone Systems

To improve our understanding of CMYK, we must compare it with the RGB and Pantone color models.

RGB

Graphic and packaging designers refer to RGB—red, green, blue—as desktop colors because they represent the colored lights used on electronic displays (computer monitors, mobile devices, TV sets, and digital cameras), whether it’s for videos, websites, and apps.

Moreover, this color model offers the most expansive range of colors—16.7 million in all. As a result, discrepancies occur between colors on screen and print, as CMYK has a narrower color gamut.

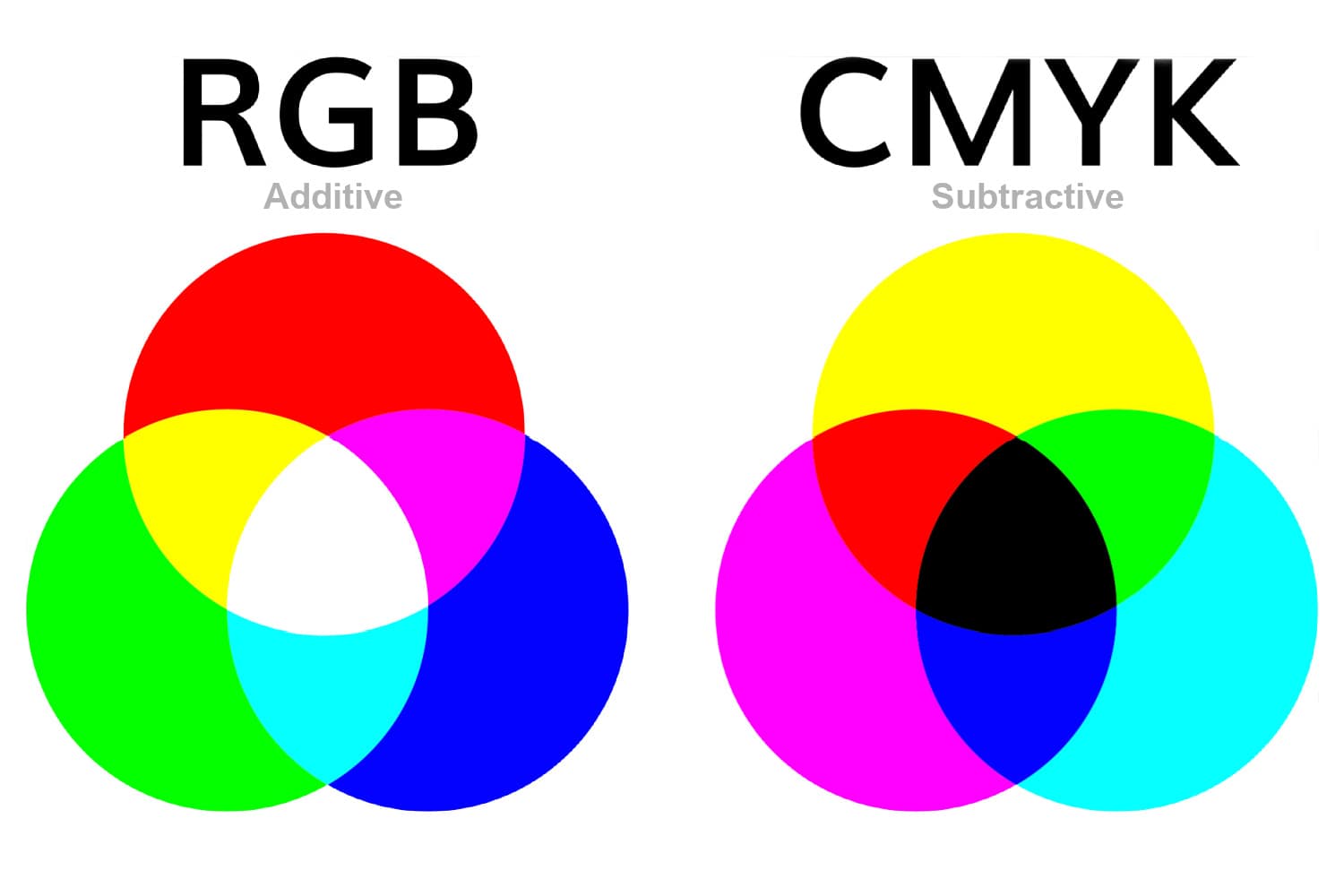

RGB vs. CMYK: Additive vs. subtractive color models

When comparing RGB and CMYK, it’s important to know that RGB is an additive color model, while CMYK is a subtractive color model.

RGB is an additive color model that combines various intensities of red, green, and blue light to produce other colors. You get pure white when you mix RGB colors at their maximum brilliance. Meanwhile, you must combine the three colors at their lowest intensity (minimal light) to produce black.

The opposite happens with CMYK, a subtractive color model. Unlike electronic screens, paper isn’t transparent and doesn’t allow light to pass through. One must apply less color to see white. Images appear with a lighter tone when paper receives fewer ink dots.

Because CMYK inks only reflect light—unlike RGB colors that emit them—it’s best to convert RGB images to CMYK for accurate printing.

Pantone

The Pantone Matching System (PMS) follows a numbering system for accurately and quickly identifying colors for printed materials, fabrics, and paints. Every Pantone color—2,161 of them—has a unique code corresponding to a pre-mixed ink formula, aiming to produce the colors consistently across different projects. These colors include fluorescent and metallic colors, which aren’t available in the CMYK and RGB models.

When you ask a professional printer to match your specific PMS colors, its staff adjusts the digital printer’s colors until the result matches your PMS swatch.

Spot Color

Spot or solid color is another name for the color printed on paper using premixed ink to match a PMS, unlike the CMYK process, which involves four layers (one for each color). In effect, the blending of colors happens before and not during printing for spot colors.

Spot colors consist of a name or number and end with either a C (coated) or U (uncoated), referring to the paper stock type on which to print it.

When to Use CMYK and Spot Color Printing

Here are some tips to help you determine when to use the four-color or spot-color printing technique:

CMYK

CMYK or process printing is ideal for projects involving so many colors that using several spot inks would be impractical and expensive. Examples include full-color photographs, paintings, and very complex colored images.

CMYK—the most widely used standard digital and offset printing system—is also cost-effective for low-quantity orders with multiple hues and gradients. However, color-matching won’t be as precise as spot colors. Some printers offer a broader range—also referred to as extended or expanded color gamut—that includes orange, green, and violet to improve brightness and realism.

Spot Color

You can use spot color printing for jobs requiring a few (one or two) exact colors, such as your brand colors and business logo, and colors outside CMYK’s color range—pastels, metallics, and fluorescents. Spot colors would cost you more per order because they require ink colors with specific formulations and a separate plate.

CMYK and Spot Printing

You can use both techniques simultaneously when, for instance, you must print an image (CMYK printing) and your company logo or product name (spot color) close to each other. Another example is when you want to increase the intensity of a specific process color or coat portions of a full-color image with a clear varnish, which is a spot color.

Below is a quick reference of the three color models—their characteristics and uses:

|

Color Model |

Color Gamut or Range |

Color Production |

Used for Printing? |

Specific Uses |

|

CMYK |

Around 16,000 |

Color layers printed in succession on packaging material |

Yes |

Full-color images (photograph, painting, complicated images) |

|

RGB |

16.7 million |

Color pixels arranged to produce new colors on digital screen |

No |

Websites, apps, videos |

|

Pantone |

2,161 |

Pre-mixed, solid color ink applied directly on packaging material |

Yes |

One to two critical colors (logo, company colors) |

Tips for Improving Color Accuracy When Previewing CMYK Colors on Your Screen

Because RGB can display more colors than CMYK, the way you see a design or image on the screen may not be accurately reproduced through the CMYK print process. But you can reduce the discrepancy between the two by following these tips:

1. Calibrate your monitor and perform soft proofing

PC and laptop manufacturers gear factory settings toward film viewers and gaming fans, resulting in high brightness, high contrast, and saturated colors.

Thus, recalibration is necessary when working on packaging designs. Adjust your device’s color settings (“color profiles” on Mac) to match your color standard, particularly the brightness or luminance of your display. Your printouts may appear dark if you’ve been designing and editing on a very bright monitor. Most monitors have built-in calibration tools

D50 is the recommended white point or white balance for LCD monitors when working with still images. White point is the temperature setting that determines the coolness or warmth of your whites.

2. Perform soft proofing

Check your software’s color management system. Adobe Photoshop and Illustrator’s soft proofing feature lets you view your artwork the way it will appear on a surface when printed by the CMYK method.

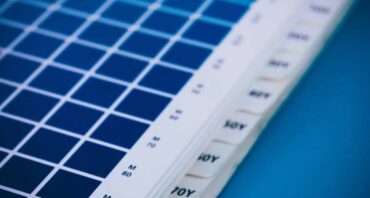

3. Refer to color swatches and guides

Printed samples of colors are a handy reference when checking designs and images on screen and paper.

4. Print a test copy

Make a printed proof to discover color problems early and avoid surprises from your printer. You can then include the printout closest to your envisioned colors when you submit your digital file to your printing partner.

Use high-quality ink and paper to avoid getting faded results. You should also check your printer nozzle and cartridge in case of banding. Otherwise, you can go to a print shop to produce a test copy for you.

Preparing Your File for Printing

After learning how to make your screen display your packaging design the way it would appear on your chosen material, you must now prepare your file for the printers.

Converting Files to CMYK

Industrial printers typically ask for files in CMYK mode so you must check your packaging design and convert it to CMYK if it’s in the RGB mode. The conversion method will depend on your software. Below, we list the steps required for CMYK conversion for the most widely used platforms.

Adobe Photoshop

- Open your image file.

- Click on “Image” on the menu at the top of your screen.

- Hover over “Mode” to display the options and click CMYK.

Adobe Illustrator

- Open your image file.

- Click on “File” on the menu at the top of your screen.

- Mouse over “Document Color Mode” and select CMYK.

Adobe InDesign

- Open your image file.

- Click on “File” and choose “Export.”

- From the options, select PDF/X-1a:2001. This automatically converts colors to CMYK.

Note that converting from RGB to CMYK may result in some color data loss and shifts because the CMYK system can’t accurately represent all RGB colors.

Communicating With Your Printer

Printing companies use different machines, so get to know their requirements, limitations, and preferences before sending your design. Ask your printer about their artwork guidelines, which typically includes the correct file format, size, resolution, color system (some have a unique PDF Preset), printing method and technology, as well as their expectations and deadlines.

Due to technological advancements, some printers can work with files in a specific RGB profile, such as sRGB IEC61966-2.1, which is compatible with most software and devices. When they receive your file, they convert it to CMYK.

Best File Formats for CMYK

We can’t emphasize enough that you’ll need to ask your printer for the file format required for your print project. Nevertheless, we list some of the best file formats below:

.ai (Adobe Illustrator)

Illustrator is the industry standard for vector-based, scalable designs, making it a standard source file for CMYK.

.pdf (Portable Document Format)

PDF preserves all the color and formatting information in a document and can handle raster and vector images. The file format is also compatible with most programs, making it ideal for CMYK printing.

.eps (Encapsulated PostScript)

EPS is a vector file format and a great alternative to .ai because it opens in non-Adobe software.

.cdr (CorelDraw)

CorelDraw files contain images created using this software, which can also generate text, shapes, and effects. You can convert CDR format to .ai., .pdf, .eps, and .tiff.

.tiff (Tag Image File Format)

Virtually all image-editing and page-layout applications support this flexible raster image file. The format allows you to choose between CMYK and spot colors.

The Reliability of Your Custom Packaging Manufacturer Is Key to Consistent CMYK Printing

Read our ultimate guide to packaging terms and definitions to help you get up to speed with industry terminology as you create your own custom boxes.

Industry insiders predict that the U.S. packaging market will rise by 2.88% to $222.59 billion by 2028 and keep its status as a leading growth driver in the offset printing press market. Digitization has penetrated this printing method, putting it head-on-head with digital printing. Computers now create printing plates, which undergo laser exposure resulting in improved image quality.

Moreover, analysts project a 5.19% growth in the North American cardboard market until 2027.

Because color is the top influencer in buying decisions—at least 85% of consumers say so—your printer must have a proven record for consistent quality output.

Refine Packaging’s customers and brands have relied on our high-spec manufacturing process for their marketing needs, from display and showcase exhibit packaging to shipping and mailer boxes, corrugated packaging, and custom labels and stickers.

Our offset printers work with CMYK and PMS spot colors. If your design is in RGB mode, we’ll convert it to CMYK. We have artwork guidelines to make it easier for you to prepare your file. Also, we’ll show you a digital proof before printing, so you can check whether the colors replicate or are close enough to your initial choices. Besides offset printing, we offer UV coating, foiling, and embossing/debossing.

Refine Packaging is the top choice for the world’s Inc 5000 and Fortune 500 companies. With super fast production times, affordable pricing, and a sky’s the limit attitude, we’ll help you turn your custom packaging into a competitive differentiator. Contact us today and a dedicated packaging specialist will guide you through every step of the custom packaging process without breaking a sweat.

Ready to think outside the box? Let's get started!

Get in touch with a custom packaging specialist now for a free consultation and instant price quote.

.svg)

Share