As you design your product’s packaging, you might’ve come across the phrases embossing and debossing, and wondered what the difference is.

Essentially, embossing raises your artwork (usually your logo) from the printed material of your packaging, while debossing does the opposite to give your artwork a sunken look.

A cocktail napkin with the company’s logo which is slightly raised up from the foundation of the napkin has been embossed. A silicone wristband with the logo stamped down on it is a debossed product.

For many products, like napkins and wristbands, the choice between embossing vs debossing is clear. But when it comes to custom packaging, choosing between embossing and debossing depends on several factors.

Let’s dive a bit deeper into both embossing and debossing to help you fully understand what they mean and when you’d want to use each one.

The Process of Embossing Your Logo Onto Product Packaging

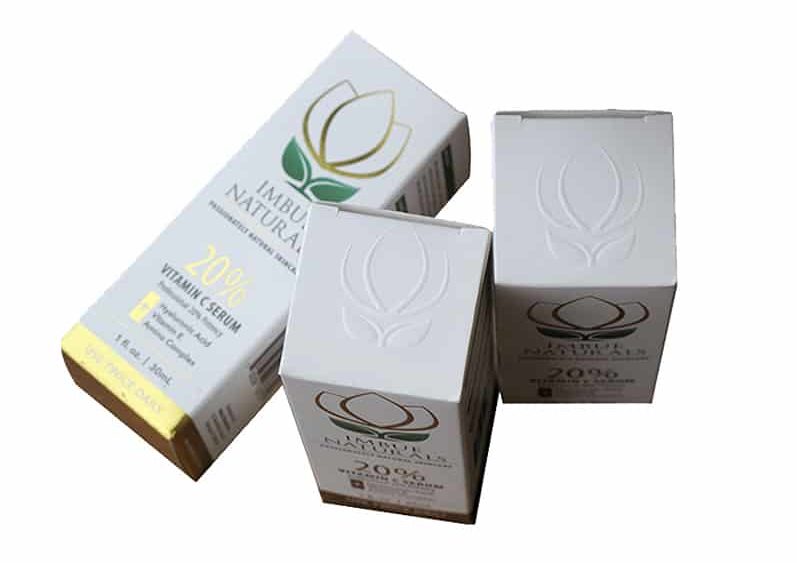

Embossed Artwork on Product Packaging

When starting out with the embossing process, a metal plate, known as a die, is created. Embossing creates the raised graphic on it that you want to emboss onto the final product.

This plate is pressed into the product underneath, raising the profile of the product design (such as the box) to stand out. This process is then repeated again and again. Because embossing dies are made of metal, they’re incredibly durable and can be used for small scale and large scale projects alike.

It’s worth noting that embossing a logo onto a product is a different process than raised ink printing (also known as thermography). This is made possible by using a special type of powder that binds to the paper when it is heated, rather than actually raising the paper itself and thereby changing its shape.

Embossing often has a higher setup cost through offset printing, however the quality is indisputable, as it adds a touch of elegance and exquisite style to a finished packaging design.

The Process of Debossing Your Logo Onto Product Packaging

Debossed Artwork on Product Packaging

The debossing process is similar to that of embossing, but rather than pressing the die underneath the product to make it stand out, debossing applies the logo downward from the top. This indents the logo into the product. While debossing is not as popular as embossing, debossing carries a unique look all its own.

What to Keep in Mind When Embossing or Debossing

There are certain design considerations you’ll want to keep in mind when deciding to deboss vs emboss. In many cases the design process will be the same, but much of this process will depend specifically on what you want to have embossed or debossed, the type of material it will be applied to, and much more. Here’s what to keep in mind:

Convert Your Artwork to a Vector Format

First, it’s important that you begin the process with vector art. If the graphic designers at Refine Packaging are designing your packaging, we’ll already have this covered.

The reason why vector art works better is that because behind the custom design itself, there are mathematical calculations that make it possible to resize the debossed design or embossed design without any loss of quality. That means it can be printed on a tiny sticker or blown up to the size of a skyscraper and still look great. Having vector artwork makes the printing process easier, no matter what type of packaging you want to create.

It’s also important that you use a simple design. The more complex the image, the more it has the chance to look skewed or distorted when made in a “3D” style format, the way logos can look when being embossed. Surprisingly, logos that have shadows, gradients and similar effects can look unusual when they’re suddenly converted into a 3D style texture, so in this case, simpler really is better. A custom packaging manufacturer can provide guidance about design complexity after receiving all your print collateral.

Select the Area of Your Design to Be Embossed

Many companies want to have their entire logo embossed. This is possible, however, embossing designs often work better if only a section is embellished, rather than the whole logo.

For example, only embossing some of the logo’s text, initials, logotype or a pattern. Again, since every project and every design is different, it’s important to consider the entire goal and the impression you want to convey in order to determine the best plan of action that will have the biggest effect on your target audience.

Enhanced Finishing Options for Added Style

Choosing embossing vs debossing is a matter of preference, but keep in mind that you can customize the look even further with different finishing options to further highlight and refine the style you’re looking to convey.

For example, dies can be customized to create a different look for the blind emboss or deboss, making them look several layers deep rather than one single raised or recessed layer. This can make your embossed graphics or embossed image look more like it is “sculpted” into the package.

There are also other accents, varnishes and laminations that can add a touch of sophistication to your packaging design, such as the choice to apply foil stamping, aqueous coating, and matte or gloss lamination

Why is Embossing More Expensive than Debossing?

You may be wondering, if both embossing and debossing use metal plates to press the design into the material, why is embossing often more expensive?

The fact is that embossing needs an additional metal element (known in the printing industry as a “counter”). This is required to actually push the die down into the material. The use of the counter increases the setup cost, so it may not be financially desirable to add that up-front cost to your print project if you only need a small batch of items printed.

If you have specific needs for your deboss, it’s also possible that this process will go up in price if you want a deep indentation in the package, or you want to cover a box and then deboss it with your logo after it’s covered. In this case, the debossing process may need to be done by hand in order to ensure better results and the high quality output you require.

Embossing or Debossing: Which Should You Choose?

We understand that a simple question like understanding the difference between embossing and debossing can have a complicated answer that is partly personal preference, but that doesn’t mean you have to figure it all out on your own.

Here at Refine Packaging, we have the knowledge, experience and expertise to help you with your packaging design and production from concept to completion.

Request a free quote today to learn more about our detailed packaging services and see why so many companies, large and small, rely on us to turn their packaging vision into reality.

Ready to think outside the box? Let's get started!

Get in touch with a custom packaging specialist now for a free consultation and instant price quote.

.svg)

Share